Menu

Indoor Air Quality

Ventilation is the replacement process of air in an enclosed volume.

Object:

To prevent the oxygen contents of ambient air,

To prevent carbon dioxide, body odors, cigarette smoke and moisture content in the ambient air from increasing dramatically

,

To discharge the heat gain arising out of machines, people and lighting equipment to outside atmosphere,

To discharge the moisture gain arising out of machines, cooking and people to outside atmosphere,

To remove toxic gases and dust from the atmosphere,

To reduce the numbers of bacteria and harmful microorganisms.

One or several of the aforementioned items may be the aim of ventilation. This section will provide the requirement of ventilation in various volumes, ventilation methods, calculation principles and installation details. The key data to be considered for building up the ventilation facility is the quantity of ventilation. Air quantity is determined on the basis of some main criteria such as fresh air requirement of human body, concentration levels of certain pollutants under the limit values, pressure control and temperature control. In the past, energy costs constituted a significant parameter for the system design.

Today, indoor air quality as well as the energy costs has become the second important parameter and mostly it predominates over the costs. Different standards which are specific to certain applications may give various figures. Turkish Standards are not determinative for this matter because of not being analyzed and detailed profoundly. The subject matter shall be discussed according to ASHRAE standards taken as a basis for indoor air quality and different data are put forward in this context.

Depending upon the ventilation forces, there are two types of ventilation; natural ventilation and mechanical ventilation. For natural ventilation, a building is ventilated by means of natural forces in a controlled way. But, mechanical ventilation is provided with a fan. The air is supplied forcibly against energy consumption.

Natural Ventilation

Natural ventilation is a conventional method used for the ventilation of buildings. Natural ventilation is a ventilation method that is cheap to install and maintain. It does not require electric power and operates silently. Windows are the key elements of the natural ventilation and the basic forces resulting in the ventilation are wind force and thermal forces. Unfortunately, natural ventilation stops when these natural forces disappear. Therefore, mechanical ventilation should be used in case of necessity. Nowadays, buildings are entirely dependent on fan-driven mechanical ventilation. However, some parameters such as energy saving, indoor air quality and the concept of sustainability require to develop new systems and solutions. In this context, the new trends came into existence for construction technology. Natural ventilation is of great importance for the buildings constructed with this new approach. According to this newly-developed approach, mechanical systems are only used when natural ventilation system does not satisfy the need. Research and development activities on this scope are heavily conducted all over the world.

Wind Pressure

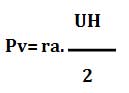

Calculation method of the wind pressure on any surfaces of the building at a certain height is explained by ASHRAE. Wind pressure on a certain wall surface that blows from a certain angle may be calculated as follows:

![]()

Wind pressure, Pv, generated by the wind coming to the surface at a right angle may be calculated with the help of Bernoulli equation:

It is a coefficient depending on UH wind speed, Cp local wind direction and building geometry and land characteristics. The exact values of this coefficient are determined by model tests. However, ASHRAE has an approach to determine the said coefficient. Cp is calculated as follows:

![]()

In this formula, Ci shows the internal pressure coefficient. If the incoming air through the openings is extracted outside from the other openings in the same floor, Ci may be taken as -0.2. Ci values are negative and mean the extraction process inside.

Pressure Effect caused by

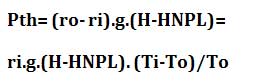

Thermal Effect (Chimney Effect)

Chimney effect arises when air density inside or outside of building is not equal. In cold winter days, air column which is heavier than the hot water inside of building, applies inward pressure for lower floors of the building. As a result of pressure difference, inside air enters into the building from the lower floor at winter time and then incoming air rises to upper floors. The exact opposite situation occurs when inside of the building is cooled in summer term. The incoming air from the upper floors moves down the ground level. As a result of the chimney effect, there is specific point in the building in the vertical direction where internal and external pressure are equalized . This point is called neutral pressure level. If the openings are positioned uniformly throughout the building, neutral plane is located at the very center height of the building from the ground level. If the building has a large vertical shaft such as atrium at the center area, neutral plane is raised to the upper part of the building and air currents and type of infiltration inside the buildings differ considerably. Pressure difference arising out of chimney effect may be formulated as follows:

i and o indices refers to inside and outside area, respectively. HNPL shows the height of vertical axis and H means the height of relevant floor. Ú and T show the air density and temperature, respectively. There is a resistance to the vertical movement of air due to the chimney effect in conventional buildings. Thus, actual pressure difference caused by thermal forces is calculated as follows:

![]()

Cd refers to extraction coefficient and experimental value for modern buildings is between 0,63 and 0,82.

Total Pressure Difference

The difference of internal and external pressure for any floor levels is calculated by means of the algebraic sum of the pressure differences arising out of wind and thermal forces. Whereas;

![]()

Calculation of Ventilation Air Volume

Flow rate of the ventilation air is calculated by the equalization of total pressure difference with openings and pressure drops (resistance to flow) in simple duct system. Accordingly;

![]()

The resistance developed against the flow should consist of all local and frictional losses and the resistance coefficient (R) should be calculated specifically for each building. The said equation may be expressed as air volume by inserting the opening sizes of A1 instead of V air speed. Air flow rate through an opening arising out of the natural forces in a given direction is calculated by considering the description below:

Here, the lower index shows the angle between the wind direction and wall surface. The volume of incoming air is calculated by multiplying the flow rate of the incoming air with time. Total amount of the air entering into the building within a certain time period from all directions indicates the total amount of ventilation.

Night Cooling

The night cooling is also possible for the buildings ventilated naturally. Night cooling is offered as an option in mechanical systems under the names of "freecooling" or "cool down".

As for natural ventilation systems, it is the characteristic of the system. When the system is activated during the night hours in summer time when external temperature is lower than internal temperature, the air cooled during the night is stored in the mass of building. If a building is designed properly and locates in an area where climatic conditions are suitable, it is possible to hold a building in comfortable conditions for all season by virtue of the stored cold air without need to mechanical ventilation. A study carried out in England indicates that night cooling allows to save energy between 5% and 40% depending on the building types under the climatic conditions of the said region. Natural ventilation and natural cooling not only save for electric power but also protects the environment and natural resources.

Mechanical (Forced) Ventilation

Mechanical ventilation is provided by fan(s) for replacing or moving the air. Mechanical ventilation is comprised of three systems:

Natural air inlet, mechanical air extraction

Mechanical air supply, natural air outlet

Mechanical air supply, called as balanced ventilation and mechanical air extraction

Mechanical system does not depend on the external conditions. Continuous air movement is provided forcibly. However, it requires a handling unit and operational cost. Furthermore, a noise problem arising out of fan and duct system may occur.

The air supplied to living areas with a fan should firstly heated up to room temperature in winter. Fresh outside air should be removed from dust and foreign substances by way of filtration. It is possible to condition the fresh outside air in mechanical ventilation system. However, air conditioning is not possible for natural ventilation systems in practical terms due to the difficulty caused by pressure losses It is possible to both control the air quantity and internal pressure with balanced ventilation provided by means of supply fan as well as exhaust fan for exhausted air. By doing so, air movements in a building can be controlled by making pressure differences. It is an indispensable solution for clean room applications without any alternative. Various recovery possibilities exist in mechanical ventilation.

For example, the energy extracted from the exhaust air can be transferred to fresh incoming air by means of heat exchangers.

Indoor Air Quality

Indoor air quality refers to the cleanliness of breathing air in closed areas. Clean air can be defined as the air containing no specified pollutant above the hazardous concentration levels determined by authorities and satisfying minimum 80% of the people, who breathe in, concerning the air quality. Cleanliness of indoor air has of growing concern to people for non-industrial areas such as dwellings, offices and schools. People spend 90% of their daily life in indoor areas and as the human population living indoor areas increases, this overpopulation will result in some specific problems. Some new concepts such as sick building syndrome have been introduced as a result of recent studies and the illnesses caused by the indoor air pollution are diagnosed. In parallel to this, the number of the relevant studies have increased, scientific articles have been published, scientific conferences have been held and binding standards have become applicable. ASHRAE 62-89, which is one of the binding standards, is the most comprehensive and detailed standard in this regard. The applicable rules of this standard (e.g. non-compliance with the principles of energy saving) have been one of the most debated issues.

Sick Building Syndrome

The term “Sick Building Syndrome” (SBS) is used to describe the health and comfort complaints of building occupants linked to the time spent in a building where no surface cause of disease or ailment can be identified. The complainants may be located in a certain room or zone of the building or scattered inside the building. Another term used in this scope is “Building Related Illness” (BRI). For BRI, the causes of diseases diagnosed in the building are identified and can be attributed to the ventilation system of building.

Symptoms of Sick Building Syndrome

Building occupants start complaining of their ailments abruptly.

These complaints are as follows: headache, eye, nose or throat irritation, cough, dry or itchy skin, dizziness and nausea, impairment of concentration and high sensitivity to odor.

The causes of these symptoms could not be identified.

Most of the complainants experienced relief from their symptoms after leaving the building.

Building-Related Disease Symptoms

Many building occupants complain of cough, chest tightness, fever, chills and muscle aches.

The causes of these symptoms are clinically identifiable.

Recovery period take a little time after leaving the building.

Causes of Sick Building Syndrome Deteriorating Indoor Air Quality

Harmful substances that damage and pollute indoor air quality may be grouped under the following headings.

Contaminants that adversely affect the indoor air quality include:

The ratio of carbon dioxide in breathing air (caused by human and animal respiration and combustion)

Odor (caused by human)

Micro-organisms (caused by environment and human)

Humidity (caused by environment and human activities such as cooking)

Radon gas (caused by earth)

Organic vapors (caused by materials and building elements)

Dust (caused by environment and used materials)

Allergenic substances and species (caused by environment)

Cigarette smoke (caused by human)

Other sources (other than aforementioned ones there are many factors negatively affecting air quality.. They range from electronic pollution to radiation).

Chemical Pollutants from Indoor Sources

The source of indoor air pollution in a building is mostly located inside that building. For example; adhesives, carpeting and upholstery, wood products, copy machines, pesticides, volatile organic compounds (VOCs) containing of formaldehyde emitted from the cleaning agents are the main indoor sources of air pollution. Cigarette smoke plays a key role in the generation of highly volatile organic compounds, other toxic compounds and respirable particles.

Researches show that the inhalation of some volatile organic compounds (also known as carcinogens) at high concentration may cause chronic and acute health problems. Many volatile organic compounds from low to medium concentrations may also create acute reactions.

Chemical Pollutants from Outdoor Sources

Incoming fresh air may be the exhausted air from surrounding buildings. Misplacement of outlets, windows and openings in a building lead to exhaust gases of motor vehicles, buildings (caused by kitchens and bathrooms) and plumbing vents entering into the building in an easy way. Moreover, the exhaust gases from the car parks located nearby may enter into building.

Biological Pollutants

Bacteria, mold, pollen and viruses are the most common types of biological pollutants. These pollutants may breed in stagnant water accumulated in ducts, dehumidifiers and drain pans or roof area, coating or insulating material. Sometimes insect or bird droppings may cause biological pollution. The symptoms related to biological pollution include cough, chest tightness, high fever, chills, muscle ache and allergic reactions such as stomach irritation and upper respiratory congestion. As already known Legionnaire's disease leads to Legionnaire disease and Pontiac Fever.

Radon and Asbestos

Sick building syndrome and building related diseases may cause acute or medium level health problems, radon and asbestos show their effects after a long time people have been exposed to them. Radon and asbestos should be examined in detail while analyzing the indoor air quality of a building. These elements not only affect human health on their own but also increase the damages of other elements under low temperature, moisture and light.

Methods for Improving the Indoor Air Quality

There are some specific methods to improve indoor air quality. First of all, sources of pollution should be controlled and eliminated. For example, prohibition of smoking, removal of indoor materials containing harmful gases such as carpets.

Capturing the pollutants at source and discharging to outside are frequently used principles in the areas of industrial ventilation and kitchen ventilation. The source of pollutants can be identified in such kinds of spaces.

Filtration and Cleaning of Indoor Air

This method can not be used effectively because there are too many pollutants in various types. But it is increasingly developing. It is the sole effective cleaning method for the areas where it is not possible to consider the outdoor air as clean.

The most common and effective method for ensuring indoor air quality is ventilation. Indoor air quality can be reached to a satisfactory level by means of supplying sufficient fresh air to indoor spaces.

Removal or Replacement of Polluting Source

This method is very effective for solving the problems related to indoor air quality when the source is known and easy to control. The filters should be cleaned or replaced periodically. Other necessary precautions include replacement the steel covering of ceiling, insulating the smoking lounges properly, allowing the pollutant source to get fresh air, storage of paints, adhesives, solvents and pesticides in well ventilated areas and use of these pollutants when building occupants are out of the building. Nobody should enter the building until the hazardous effects of chemical substances disappear.

Increasing the Ventilation Rate

In general, the cost of increasing the ventilation rates and air distribution in order to reduce pollution in a building is very high. However, ventilation is a key parameter for ensuring the indoor air quality. Ventilation systems of buildings should be designed in such a way that they will meet the local construction standards. If necessary, ventilation system could be installed above the standards. When pollutant source is very strong in the building, local exhaust system has crucial importance for venting the polluted air to outside. Local exhaust ventilation is partially used in the rest rooms, photocopy rooms and printing rooms where pollutants accumulate in a specific areas.

Air Cleaning

Air cleaning can be used as a supplementary method for source control but its field of application is very limited. Particle control devices such as furnace filters are cheap but ineffective in capturing the small particles. High-capacity air filters to be used for capturing tiny particles are much expensive in terms of installation and operation. Mechanical filters cannot capture the gaseous pollutants Such kind of gaseous pollutants may be removed by means of adsorbents but these devices are expensive and they requires frequent filter replacement.

Mech. Eng. Yavuz Isman

GES Teknik

Tesisat Market Magazine 05.2009-Issue No:124